Sugar Manufacturing

After sugar cane is harvested, it is crushed near the boiling house. The cane can be stored at room temperature for a few days to a week, but its quality will gradually decline over time. Once crushed, it needs to be processed quickly to prevent the sucrose from converting to invert sugars. The processing of sugar cane is remarkable because every part is utilized:

- The juice is extracted by crushing the cane, and the remaining bagasse can be used as:

- Food for cattle and horses

- Fuel for the boiling pan fires

- The extracted juice is boiled to concentrate into sugar crystals. The byproduct, molasses, can be used as:

- A source of invert sugar for fermentation

- An ingredient mixed with lime to create durable, water-resistant concrete

- A sweetener in cooking

- Bagasse removed from the mill was laid out in the sun, and turned frequently to allow it to dry and become a fuel.

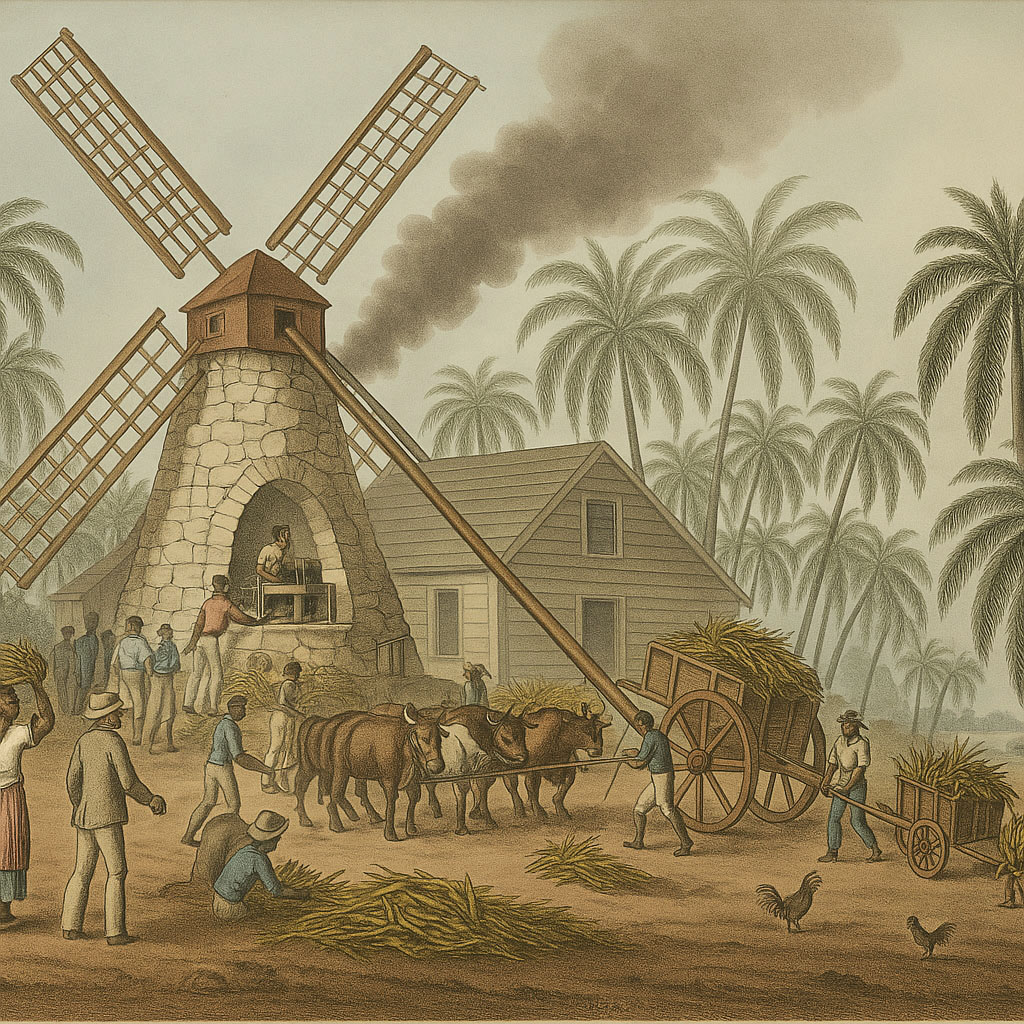

Processing sugar was a labor-intensive process that involved several stages:

1. Move the cane juice to the boiling and curing house.

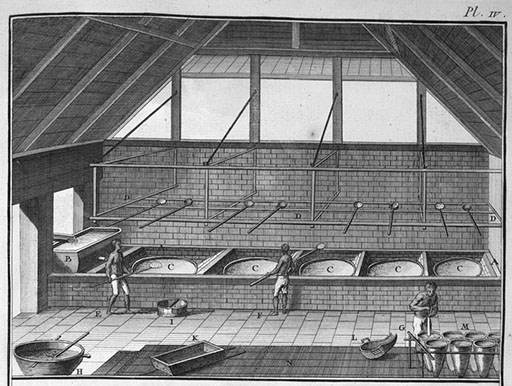

The boiling house consists of multiple pans, all heated from underneath, cooling trays, and a designated area or section for the crystallizing sugar to drain. I am unsure of the factory depicted in this picture; however, it effectively illustrates the workflow concept.

2. Introduce the juice to the empty copper kettle, which is already heated. This process, also known as the “purifier” or “copper,” involves subjecting the cane juice to rapid heating. This rapid heating kills the enzymes responsible for converting sucrose to invert glucose and fructose.

This picture shows one of the two purifiers at Estate Balenbouche on St. Lucia, still owned by the Lawaetz family. The estate utilized a large overshot water mill to crush the cane. The cane was then transported a short distance of less than 20 feet in a concrete channel that runs in front of the two coppers. A diverter in the channel was used to select which of the two coppers the juice would flow into. The drains in the coppers, which are at a higher level, facilitated the movement of the purified juice into the first of the iron boiling kettles, enabling a continuous process flow.

3. The process continues by transferring the purified juice to the initial iron kettle, also known as the “clarifier.” Here, a small amount of lime water, which is Calcium Hydroxide (quick lime dissolved in water), is introduced to adjust the pH from slightly above 4.0 to around 7.5. Subsequently, a coagulant like bulls’ blood, egg whites, or another substance is added to solidify around the impurities. As the juice is heated and skimmed, the impurities are removed, and the heating process continues to decrease the water content. The juice undergoes a series of steps in various pans to create a dense syrup, which is then transferred to cooling trays. A proficient Sugar Boiler plays a crucial role in determining the optimal timing for transitioning the syrup and identifying when it is ready to cool and crystallize, adding significant value to the entire process.

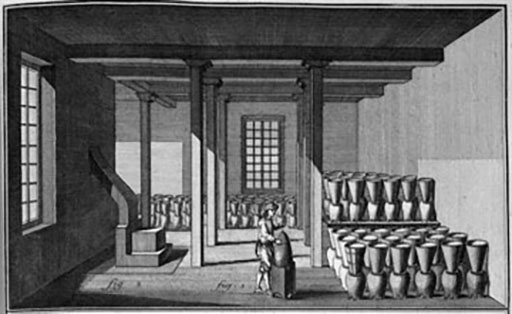

4. When the syrup is deemed to be crystallizing, it is transferred into conical clay molds within the curing house. These molds are placed on top of a collection jar, and over several days, water is poured into the mold to rinse the sugar crystals.

This image shows a clay mold and jar and a cone of crystalized sugar.

The clay mold has a small hole that is blocked with fibrous material to allow the cone to drain.

The muscovado sugar, the final product, was sent to Denmark for further processing into white sugar. The thick liquid gathered in the container is molasses, which can be utilized for making rum through fermentation and distillation, as well as being added to concrete mixtures.

In 1876, the Danish government sponsored the construction of five large cane crushing stations at Estates Fair Plain, Glynn, Barren Spot, La Grande Princess, and at Peter’s Rest, with the latter being the largest station. Cane juice from these estates was transported through extensive pipelines to large tanks at Orange Grove (now Cruzana) and then onwards to a Central Factory located on the shore near Christiansted.