Types of Sugar Mill

A sugar mill is a sophisticated industrial facility specifically created for processing sugarcane into different sugar products. However, on St. Croix, the term ‘mill’ is solely used to describe a machine employed in crushing sugarcane or extracting water from a well. In this context, I will discuss the cane crushing sugar mill..

There were four types of sugar mills used progressively on St Croix: Animal mill, Water mill, Windmill, Steam mill.

There are several locations where these types can be seen. The easiest one to visit is Estate Whim, located off Centerline Road near Frederiksted. Estate Whim, operated by The St. Croix Landmarks Society, serves as a museum and archive library where three of the four mill types are displayed on the grounds. Additionally, the remnants of a water mill can be observed at St. George Village Botanical Garden. This is the only known instance on St. Croix that I am aware of, although there may be others.

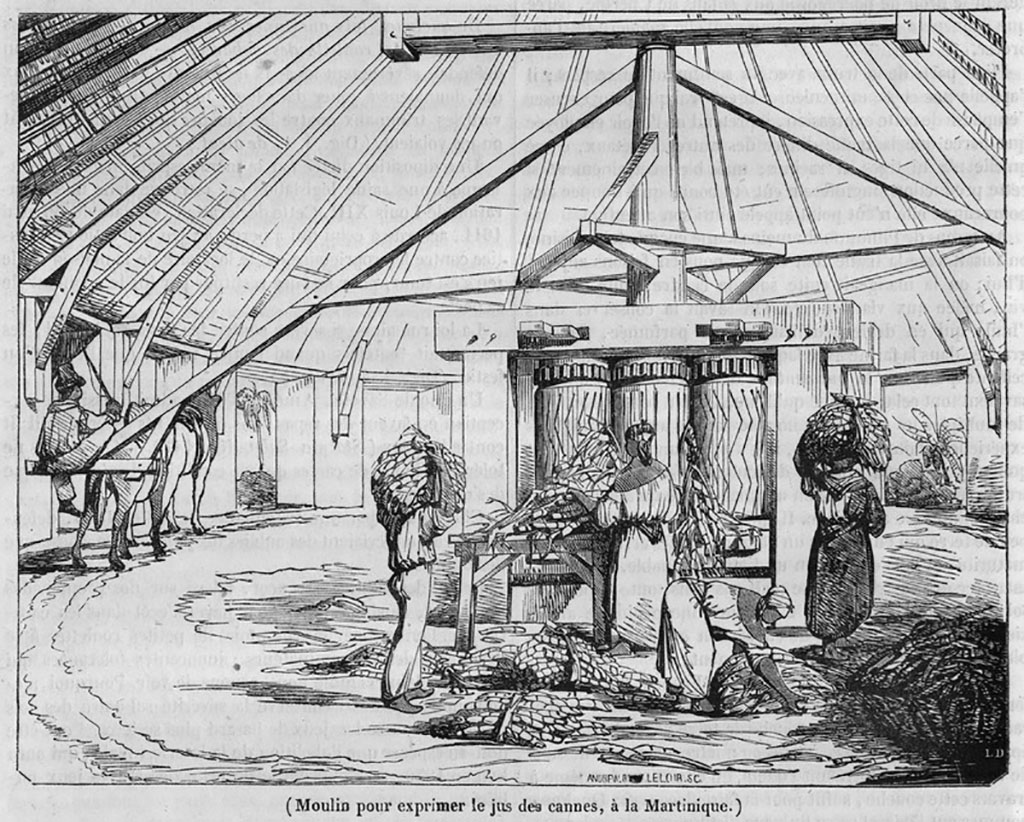

It is worth noting the wedges in the slots above and below the outer rollers, which are used to adjust the size of the gaps. The truly observant will notice the direction the animal is traveling, the rotation that this will cause, and that the cane is being inserted to the left, with the bagasse collected on the right. That’s the French for you!

At the heart of the sugar mill are the crushing rollers. They are arranged in a group of three, with the center roller being driven and driving the outer two through gears. This setup is illustrated in a picture of an animal mill on Martinique.

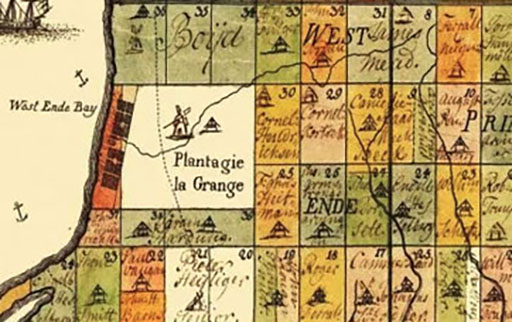

The animal mill is the earliest type of mill used by the French and the Danes on St. Croix. Soon after its introduction, windmills were added, as depicted on the Beck map of 1754. Initially, the mill rollers were made of wood and mounted vertically in a heavy wooden frame. As power levels increased, copper or iron sleeves were added to the rollers.

To extract juice from the cane, it was fed between the center and right-hand rollers, then manually returned to the smaller gap on the left for further squeezing. In efforts to improve efficiency and reduce manual labor, a curved plate called the “dumb return” was installed behind the center roller. This plate automatically fed the cane back into the gap between the center and left-hand roller.

The extracted juice would flow into a catchment box, from where a drain carried it by gravity to the factory. Bagasse, the fibrous residue left after crushing sugarcane, was used as fuel in the boiling house or lime kiln.

In the updated, colorized Beck map from around 1784, sugar windmills have been added alongside animal mills in various places, notably visible on Estate La Grange. This addition may indicate a response to increased production demands or serve as a backup when there was not enough wind to power the windmill.

The animal mill at Estate Whim is depicted alongside a painting from 1823, of a sugar windmill in operation. This painting is valuable for understanding the process. Contrary to common belief, the windmill sails are not located at the front of the mill as seen at Estate Whim. The painting illustrates bundles of cane being brought from the field, already stripped of leaves, and loaded onto Ox-drawn carts. In the scene, a woman is carrying a bundle of cane to the main entrance where a man is transferring the individual canes from a feed ramp into the first crushing roller. Not visible in the painting is another man to the left of the feed ramp who is collecting the bagasse and passing it out through the opening known as the “bagasse slot.” Adjacent to the mill base, a woman is seen loading bagasse into a wooden barrel. Additionally, there are other slots in the stonework, including the “machine slot,” a tall slot that facilitates the installation or removal of the long drive shaft.

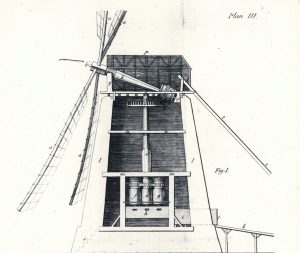

This schematic partially illustrates the fundamentals and the transmission from the sails to the rollers. The pole, as depicted in the painting above, is utilized to rotate the cap on a cast iron track and remains fixed in place once the sails are properly adjusted

The water mill remains at St. George Village Botanical Garden can be better understood by comparing them to a more intact example like the 12th-century Watermill of Braine-le-Château in Belgium. In the Belgian watermill, the wheel shaft is supported on the side wall of the channel and passes through a hole in the grinding house wall. Conversely, at St. George, the side walls have collapsed into the channel, but remnants of the hole leading into the grinding house on the right are still visible.

Efficient and economic methods for crushing cane were in demand, leading to the consideration of steam power as a solution. The first steam mill was set up at Estate Hogansborg in 1816, but it faced reliability issues, frequently breaking down. A successful steam mill was later established at Estate Spring Garden in 1855.

The emancipation of slaves and the introduction of “Contract Day” brought about significant changes. This period, coupled with seven years of unrest, resulted in increased operating costs. These challenges emerged just forty years after the Napoleonic wars, during which sugar beet production in Europe had gained momentum. The rise of sugar beet cultivation became a key factor in the declining demand for sugar from St. Croix.

As a consequence, many estates faced closure or foreclosure, while freed slaves encountered difficulties in securing contract work. The remaining estates were compelled to optimize operations to cope with the changing economic landscape.

The steam mill from Estate Spring Garden was transferred to Estate Mount Stewart, where it operated until 1892. In 1976, it was donated to the St. Croix Landmarks Society and is currently showcased at the Estate Whim grounds. Estate Rust-op-Twist also preserves remnants of a steam mill, alongside its impressive windmill and animal mill foundation. Please note that this is private property. Additionally, there is a water windmill located in the nearby bush.

Estate Annaly features a well-preserved steam mill, exemplified in the accompanying images. Once again, please remember that this is private property.

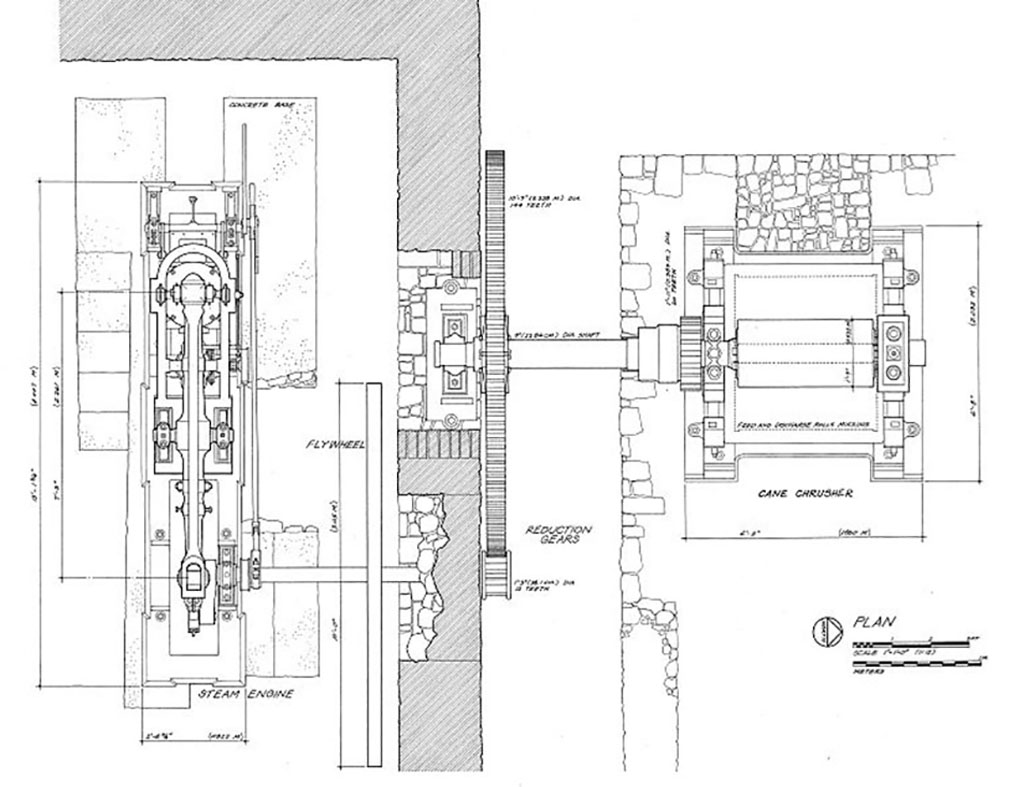

The diagram displayed here illustrates the layout of the steam mill located at Estate Rust-op-Twist, providing valuable insight into the various elements comprising a steam mill.

The increased power generated by the steam engine, along with its smaller size, resulted in various changes. One significant change was the reorientation of the rollers to a horizontal position, and making them more robust. These rollers were housed in a cast iron frame with adjustable trunnion blocks, allowing for precise adjustment of the gaps between the rollers.

At Estate Annaberg on St. John, it was observed that an animal mill could crush approximately 50 cartloads of cane per day, while a windmill could crush about 100 cartloads. This suggests that a windmill only provided double the power of an animal mill at the crushing rollers. Estimates indicate that a traditional Dutch windmill, which served as the model for the St. Croix sugar windmill, had a power output ranging from 16hp to 18hp, although it is believed to be closer to 10hp.

The Spring Garden steam mill, now located at Whim, featured an 11-inch cylinder and a 30-inch stroke. Operating at 40-60psi, it generated around 25hp and could crush 20-30 tons of cane in a 12-hour period.

On the grounds of The Buccaneer (Estate Shoys), there are multiple cast iron crushing rollers. The origin of these rollers is unknown to me, but I believe they may have originated from a steam mill due to the appropriate coupling on the central roller for connecting the drive shaft.

The mills had been consolidated to only a few locations by the mid-1900s due to the growing demand for efficiency and throughput. The machinery had also grown in size, as depicted in the images of the Bethlehem Old Works mill.

- Wikimedia Commons Photograph taken by Pierre 79. Free of use ↩︎